> Home

> CONTACT

> Fanuc Spares

> Siemens

> Fanuc Servo Drive

> Fanuc Repair

> Fanuc Alpha

> FAQ

> Fanuc Parts

> Indramat Drive

> Fanuc Parts Online

> Help

> Text Version > XML

|

|

|

|||||||||

|

|||||||||||

|

|

|

|

|

||||||||

email:click here

Re-engineering !! NO longer available !!

Machine Re engineering

Problem "if only our key machines were more accurate, faster, productive ….?". Yes, you could replace with new but how quickly will you get the investment back? But you have to improve!.

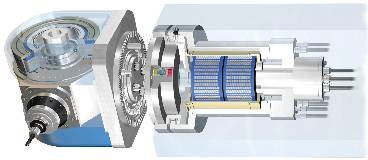

Re-Engineering means adding/incorporating the latest technology to your existing machine: It's an alternative, cost effective solution which should always be considered.

Benefits Re-Engineering can bring are:-

- Improved methods and accuracy with new tooling systems.

- Reduced set-up time plus the benefit of allowing inspection at the machine if probing is retrofitted.

- Reduced job cycle times by installing Toolchangers.

- Enable one-hit machining with 'C' Axis and Live Spindles.

- Improve quality and faster cutting times by fitting high speed spindlescoupled with drives, tooling and control software.

- Improved part control by evaluating machine accuracy and performance through laser measurement.

- Improved machine accuracy by inserting errors, found at the machine during accuracy calibration, into the control.

- Fast data transfer and communication via Computer/CNC/Networking.

- 5 axis profiling by fitting 2 axis CNC heads

Fanuc Spares - Indramat Spares - Okuma Spare

Would you like to consider features we can add to your machine? Then please hit '>contact details' above

© 2025 Fanuc Spares UK | brand names & trademarks are property of their respective owners all rights reserved